Process and pressure equipment

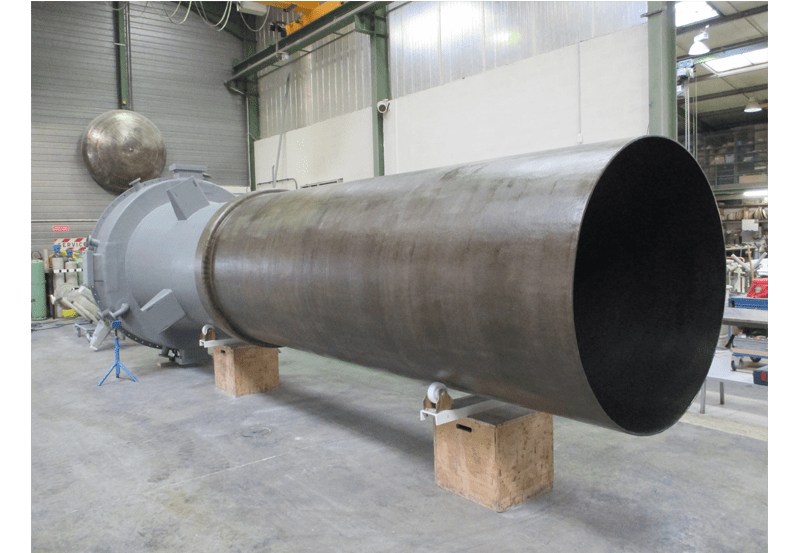

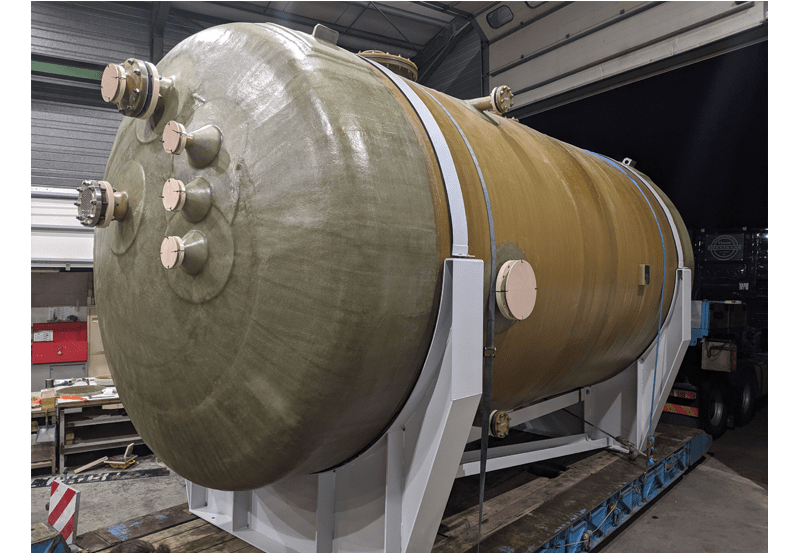

We are specialized in the manufacturing of thermoplastic, thermo-bonded and composite boiler-made equipment (MTP, MTP dual laminate and GRV).

Our anti-corrosion solutions include a synthetic, fiberglass or carbon fiber thin layer, and a fluorinated synthetic thermoplastic liner.

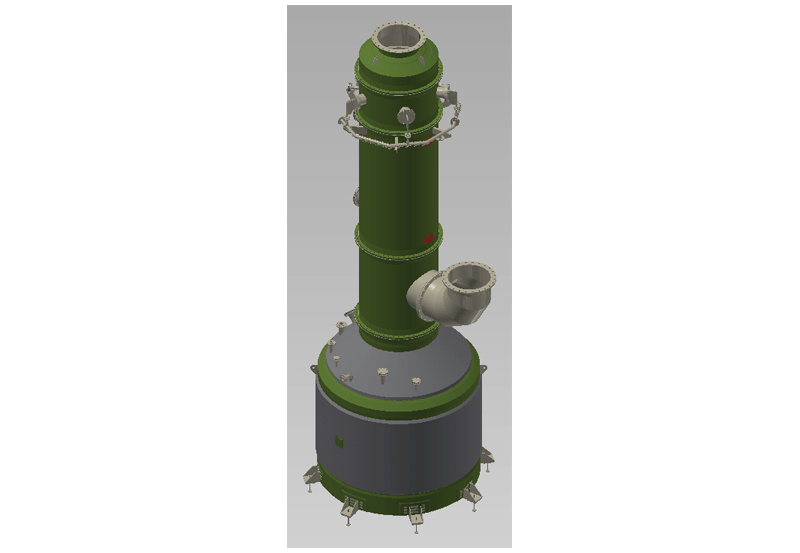

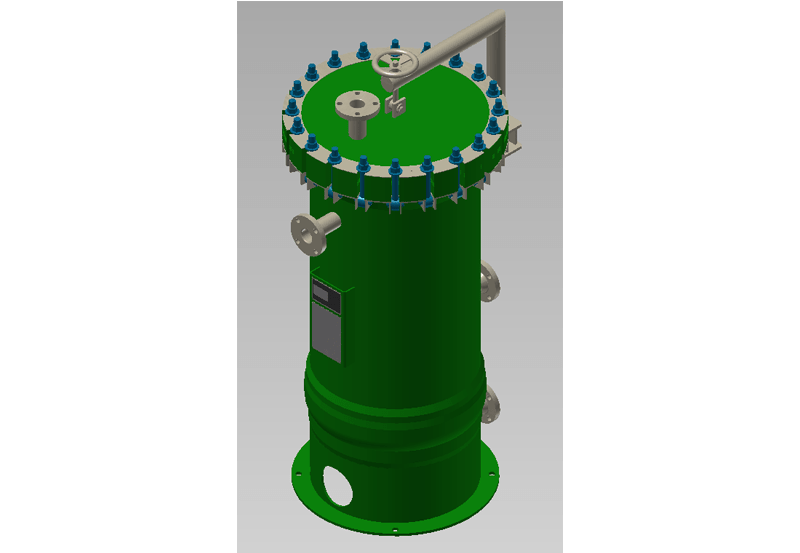

Boiler-made equipment

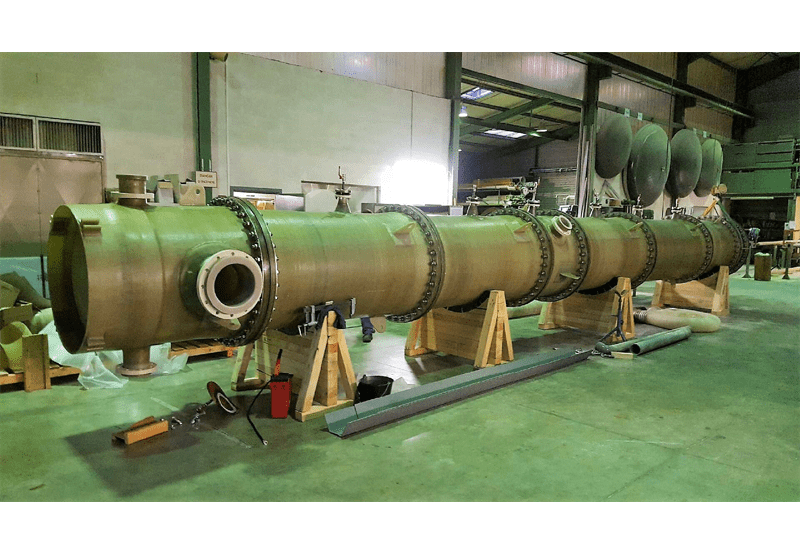

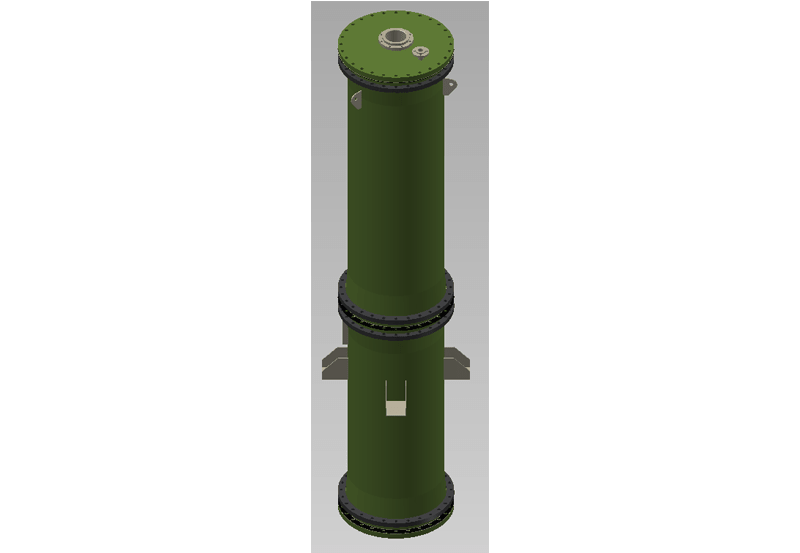

PFA Composites designs and produces columns, process tanks, washers, quenches, thermoplastic, thermo-bonded or composite centrifuges and reactors to treat, transform, store and transport solid, liquid or gaseous solutions which are highly corrosive and demanding (Ultra Purity, High Temperature, Food Compliance).

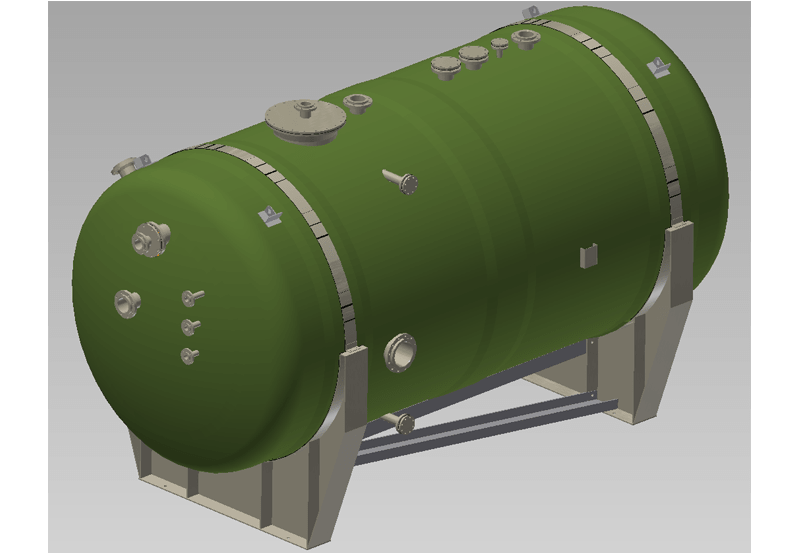

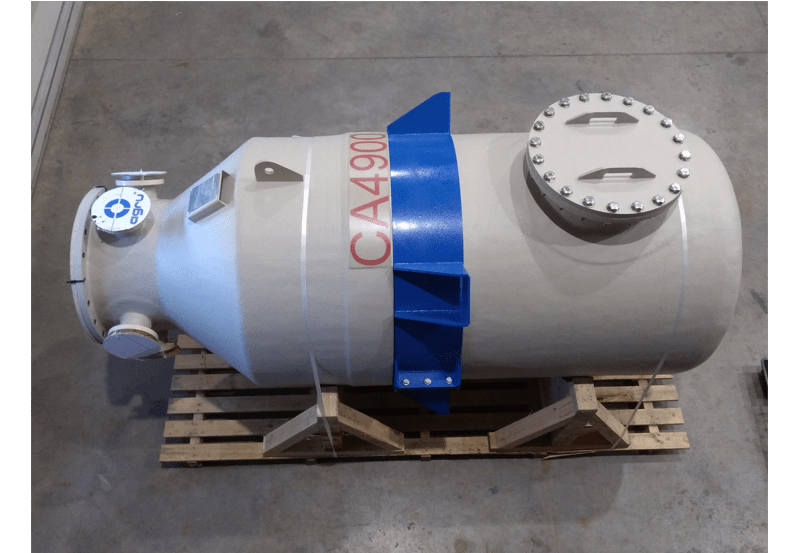

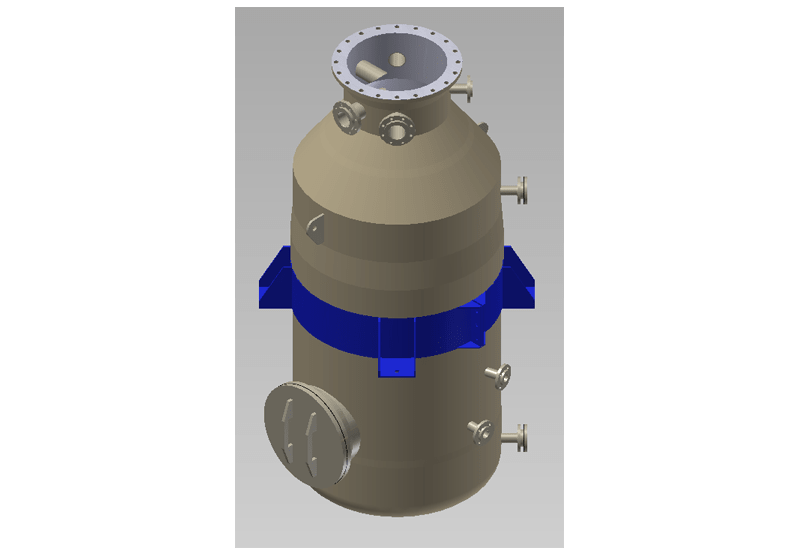

Pressure equipment and filters

PFA Composites designs and produces thermoplastic, thermo-bonded or composite pressure equipment and filters which are resistant to absolute pressure and to working pressures exceeding 10 bars.

Equipment in conformity with the Pressure Equipment Directive (2014/68/EU).

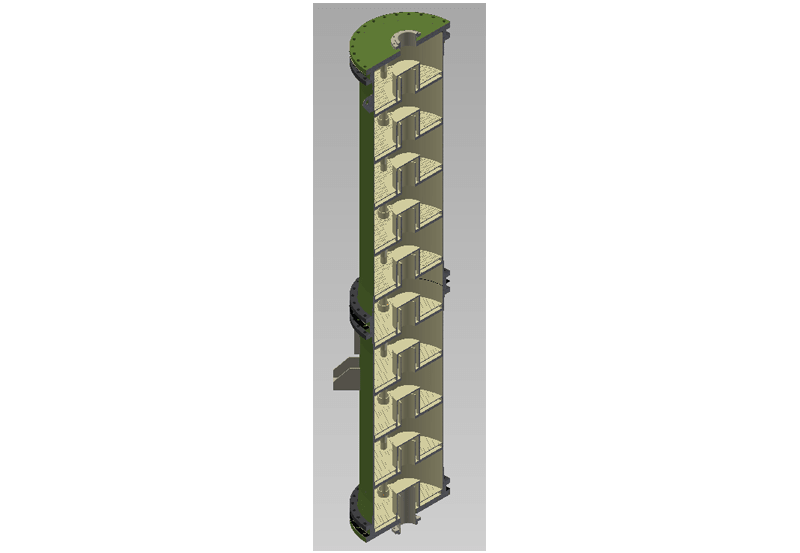

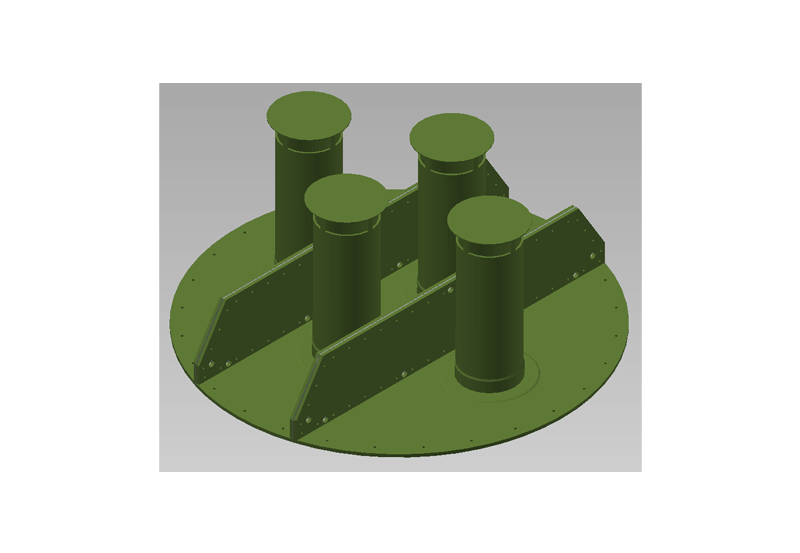

Internal and technical parts

PFA Composites designs and produces thermoplastic or composite clamps, demisters, distributors, plates, ramps, rollers and turbines which are used to separate, spray and dry fluids and smokes.

This equipment is meant to be placed inside boiler-made equipment.

.

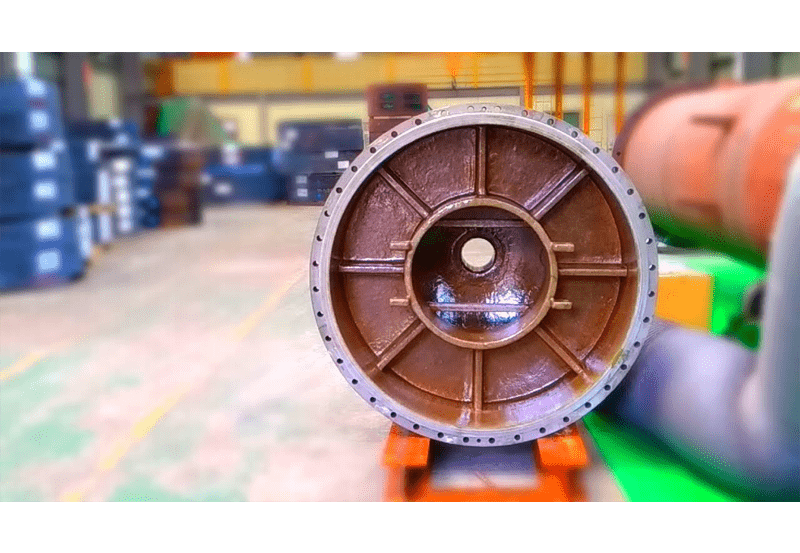

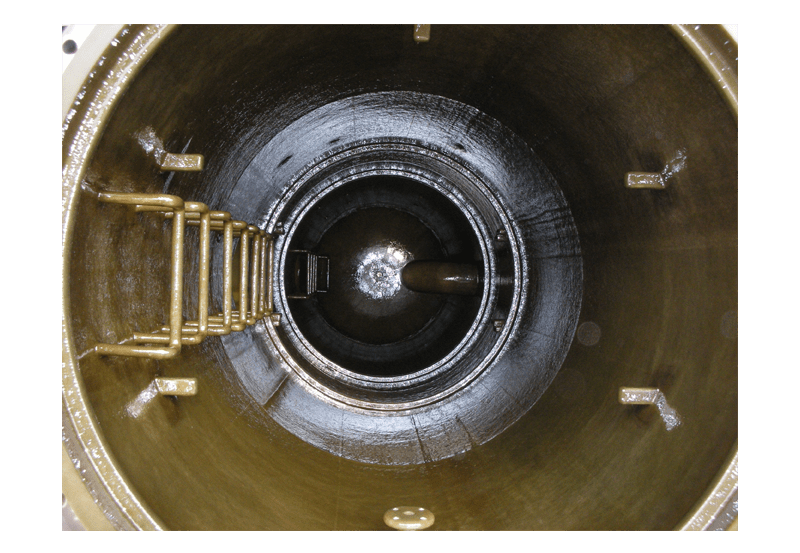

Lining

PFA Composites advises and applies linings to existing frames. These can be thermoplastic or composite linings.

The fixation element can be bonded, laminated, spot-welded or freely attached to these linings and their frames

High field of application: Corrosion, Ultra Purity, Food Compliance and Temperature.

.

Contact us

Head office

85170 Dompierre-sur-Yon

+33 2 51 34 17 18

commercial@pfacomposites.com

Lyon Factory, Aubert Site

13 Rue du Périgord

69330 MEYZIEU

+33 4 78 31 00 22