Maintenance and building site solutions

PFA Composites’ complete service provides its clients with SVR anti-corrosion solutions (stratified glass and resin polyester or vinylester) for tanks, piping and turnkey equipment. Funded in 1950, PFA Composites is highly qualified and experimented to meet your needs.

PFA Composites offers integrated solutions for the transportation, storage and treatment of liquids, powdery substances and corrosive gases for food products, the chemical industry and wastewater, energy production, as well as many other industrial equipment.

Inspection, control and diagnosis

Equipment reliability, expert assessment, control, chemical stability

Following our expert assessments, we provide you with a report and photos, and we commit to advise you on the equipment durability and

its continuous operation.

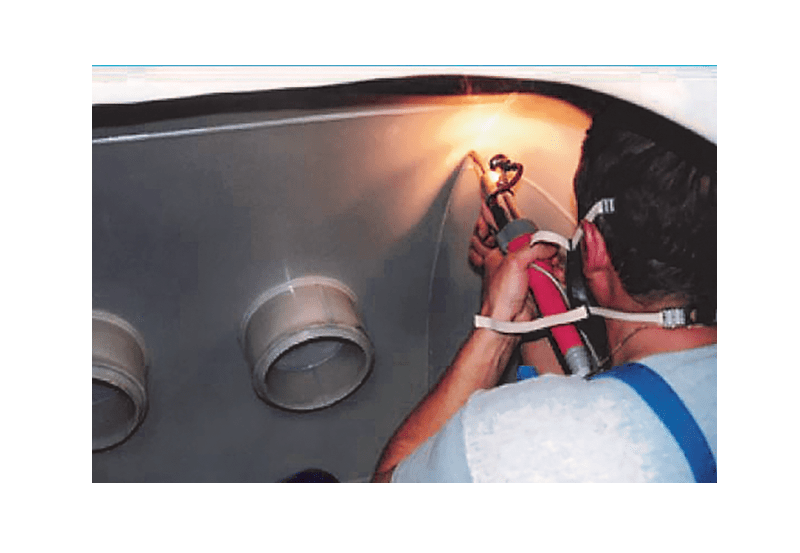

Maintenance, repair and upkeep

Optimization of your production tool

Following our expert assessments, we provide you with a report and photos, and we commit to advise you on the equipment durability and its continuous operation.

Interventions for modification, repair and improvement of your composite equipment.

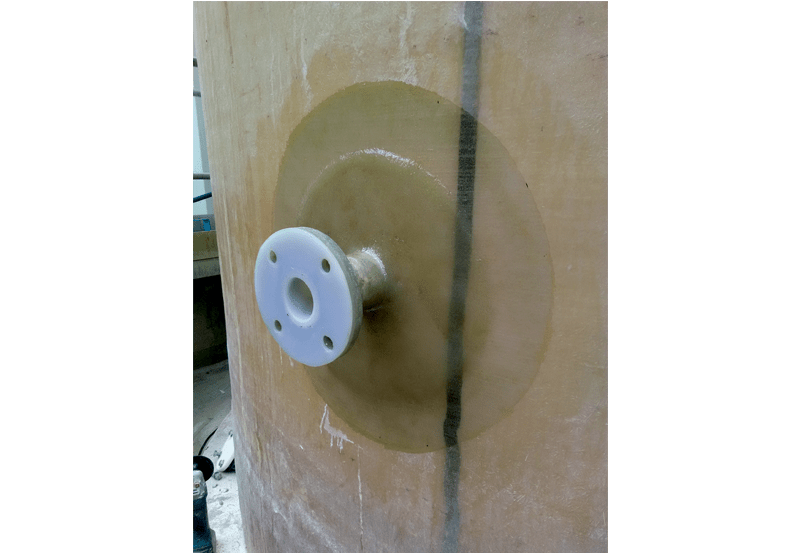

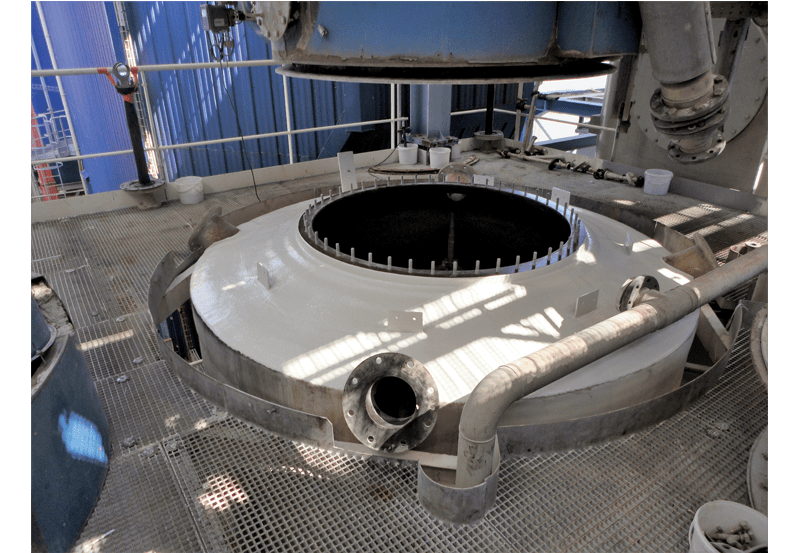

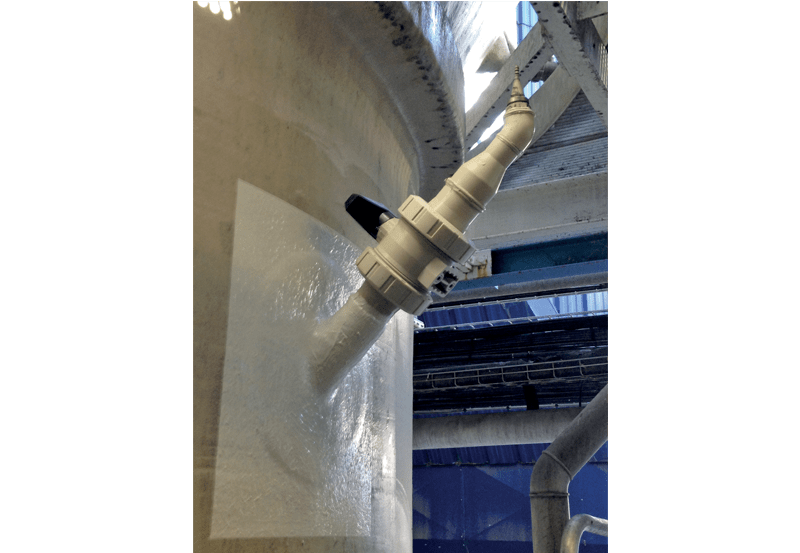

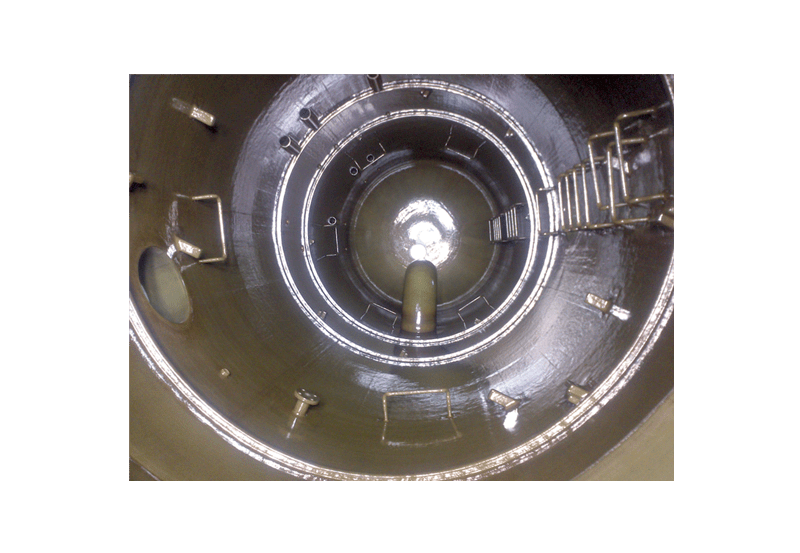

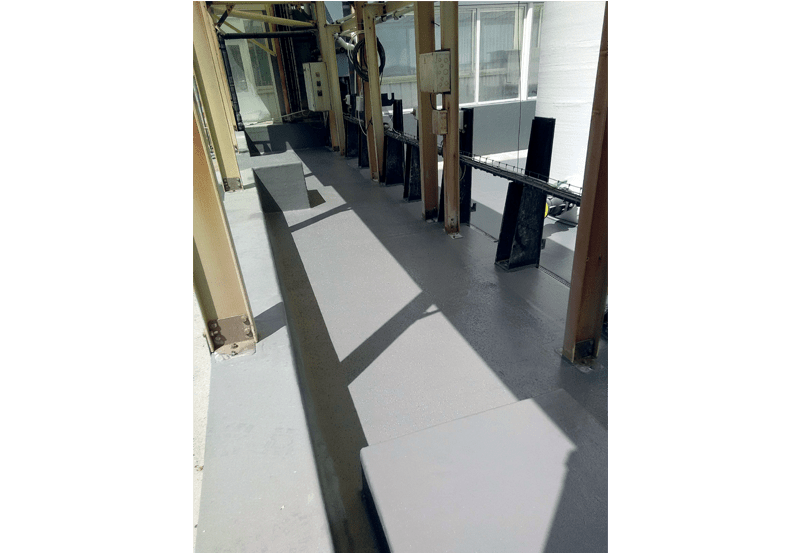

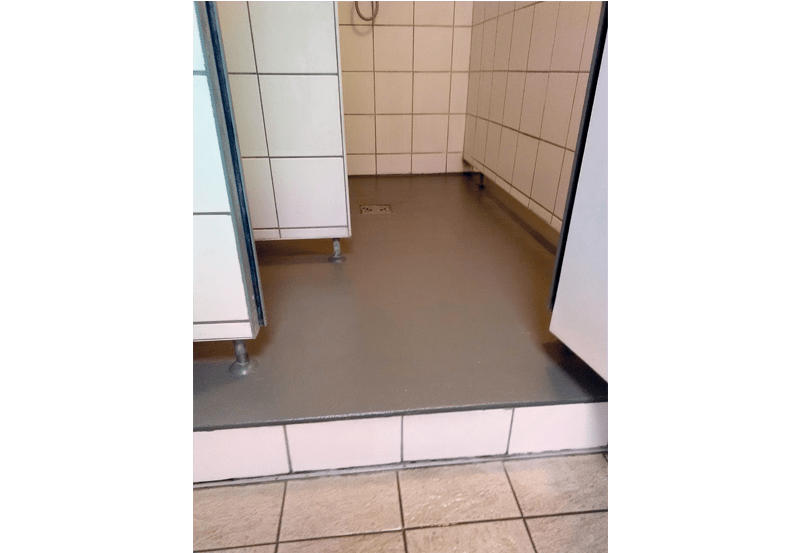

Linings

Retention, internal restoration of capacities, floors

Application of a corrosion protection to different materials: concrete, steel, stainless-steel, tiling, wood, with glass / resin laminated lining (DK 411.350, DK 470.300, DK 441.400, DK 510.A40, DK 470.HT.400, DK 8084) or thermoplastic liner (PE, PP, PVC, ECTFE, PFA).

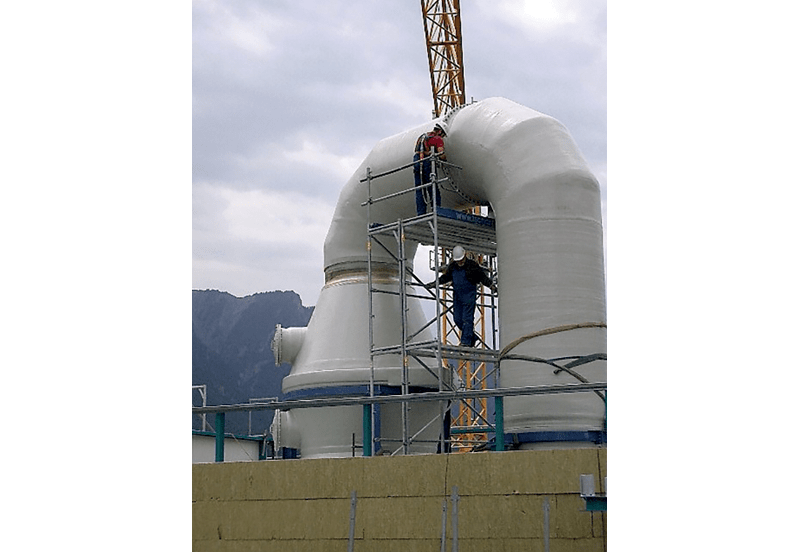

Turnkey installation

Study, supply, handling and installation

• Removal and destruction of existing installations.

• Installation of our equipement and technical assistance on site.

Food compliance

Our services comply with human and animal feed, in accordance with the law and directives:

• CE n° 1935/2004

• EU n° 10/2011

Our global and specific migration testings have been made on our laminated assemblies (resins + cloths + catalysts).

These tests comply with the law, they are adapted to CEP systems whose temperature can exceed 70°C and contain no bisphenol A. These certifications are related to both the realization of our tanks and our interventions on site (a gray pigment may be added on demand, to any equipment).

The results of these tests are at our clients’ disposal on demand.

Advantages

Restore and make the equipment comply with the applicable food standards (you save up to 50% compared to a replacement).

• Possibility to carry out clean-in-place sequences (resistance to high temperature, up to 70°C).

• Anti-corrosion.

• No Bisphenol A.

• Solution adaptable to any kind of environment (enclosed space, dangerous area or with complicated access… etc.)

• Rapidity of intervention on your sites throughout France.

• Turnkey service; studies, supply and installation.

• Wide range of basic materials: concrete, steel, stainless-steel.

Opt for security…

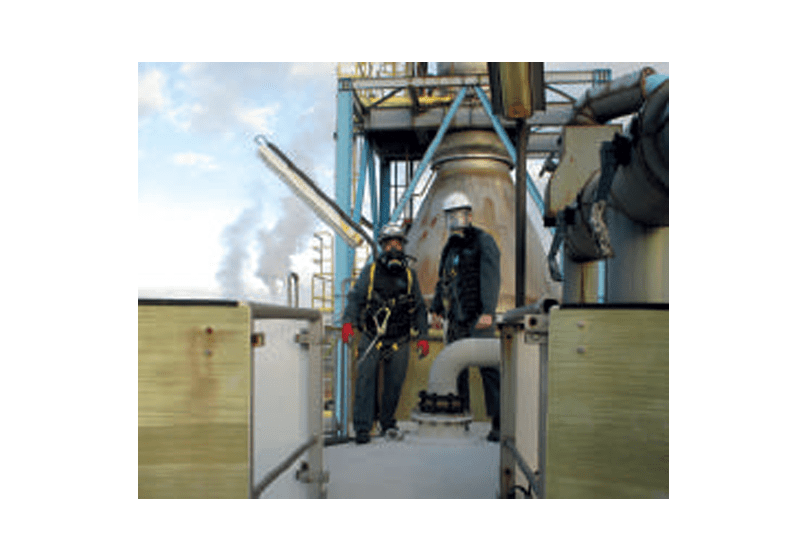

Our maintenance teams are experimented and take regular training courses.

• N1 N2 (chemical hazard),

• CACES (Certificate of Operator Safety Competency),

• Working at heights / Scaffold,

• Bridge operator / Head crane operator

• EDF prevention of electrical hazards,

• Workplace first-aider

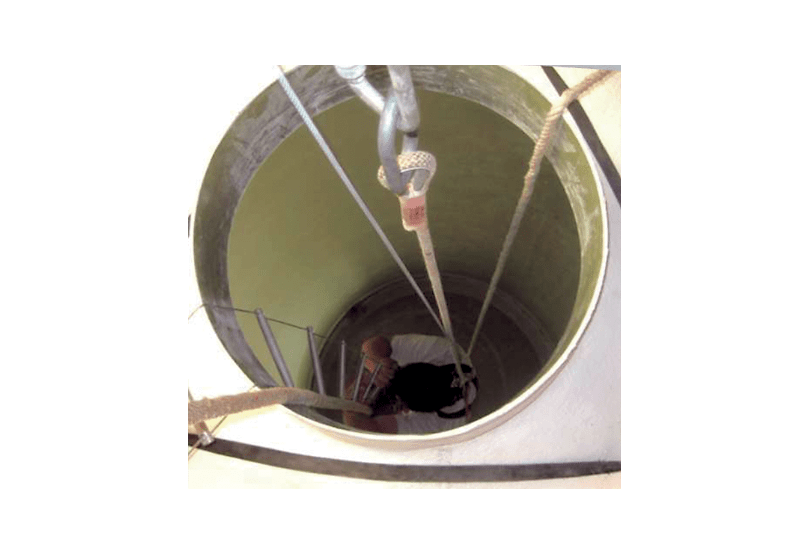

• Our teams are specialized and equipped to work securely in enclosed spaces: tanks, evaporators, chimneys, pits, retention tanks…

… and reliability

• Diagnoses with technical and commercial propositions in terms of repair and optimization,

• Expert assessments and repairs made by qualified professionals,

• Quality materials adapted to your service conditions,

• Manufacturer’s guarantee.

Contact us

Head office

85170 Dompierre-sur-Yon

+33 2 51 34 17 18

Lyon Factory, Aubert Site

13 Rue du Périgord

69330 MEYZIEU

+33 4 78 31 00 22